在电线布线和安装领域,选择正确的组件对于确保安全和性能至关重要。 DIN 导轨安装接线端子 是各种电气应用中必不可少的元件之一。本指南将指导您选择适合您电气需求的接线端子时需要考虑的因素。

目录

什么是 DIN 导轨安装接线端子?

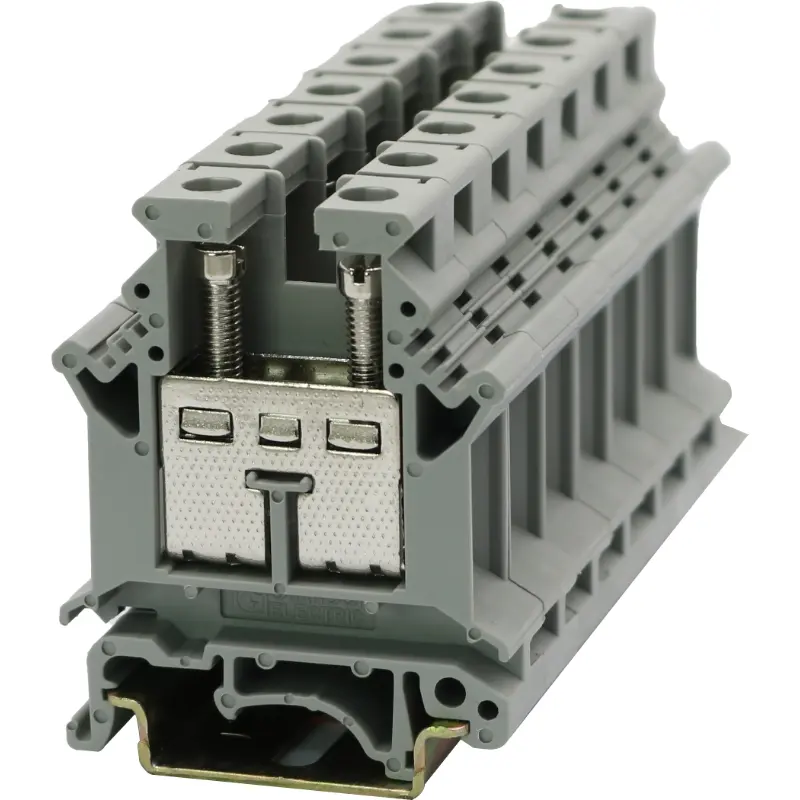

DIN 导轨安装的接线端子用于连接电路,并提供安全有序的布线管理方式。这些接线端子通常安装在 DIN 导轨(标准化金属导轨)上,易于安装、维护和升级。无论您使用的是低压系统还是高功率装置,选择合适的接线端子都能确保正确的电流处理和安全。

选择 DIN 导轨接线端子时需要考虑的关键因素

1.额定电流和电压

每个接线端子都设计用于处理特定的电流和电压。选择符合或超出您系统电气规格的接线端子至关重要。接线端子过载可能会导致过热、系统故障,甚至火灾。请务必查看制造商的数据表,以获取准确的额定信息。

2.结构材料

接线端子由多种材料制成,每种材料各有优缺点。常见材料包括:

聚酰胺(PA): 由于其耐用性和耐高温性,通常用于通用应用。

聚碳酸酯(PC): 一种高强度材料,非常适合机械应力较高的环境。

黄铜或铜: 用于导电,特别是在高功率应用中。

材料的选择应与接线端子使用的特定环境条件相一致,包括温度、湿度和机械应力。

3.尺寸和安装类型

DIN导轨接线端子 有多种尺寸可供选择。尺寸取决于您的电气系统的布线要求。接线端子必须牢固地安装在 DIN 导轨上,DIN 导轨通常有三种标准尺寸:35 毫米、15 毫米和 7.5 毫米。

选择合适的尺寸时,请考虑面板的可用空间以及需要连接的线路数量。此外,还要考虑是否需要螺钉式或弹簧式端子,具体取决于安装和维护的便利性。

4.安全特性

电气安装的安全至关重要。请寻找具有以下附加安全功能的接线端子:

绝缘盖可保护用户免于意外触电。

无螺丝连接,安装快速可靠,无不当拧紧的风险。

锁定机制可防止维护期间意外断开。

5.环境条件

每个接线端子都设计用于处理特定的电流和电压。选择符合或超出您系统电气规格的接线端子至关重要。接线端子过载可能会导致过热、系统故障,甚至火灾。请务必查看制造商的数据表,以获取准确的额定信息。

6.易于使用和安装

选择易于安装和维护的接线端子。寻找带有清晰标签和颜色编码的端子,以减少接线错误。一些接线端子采用模块化设计,可轻松扩展接线配置。

7.连接类型

连接电线到接线端子的方法可能有所不同,从而影响安装速度和可靠性。

螺丝端子: 提供牢固、安全的连接,但安装时需要螺丝刀。

弹簧夹端子: 允许快速、免工具连接;非常适合需要频繁更改的应用。

推入式端子: 简化连接过程——只需将电线推入到位即可。

优点和缺点:

螺丝端子: 更可靠但安装速度较慢。

弹簧夹: 安装快捷,但在剧烈振动下可能不太牢固。

8.附加功能

寻找能够增强可用性和功能性的接线端子。

测试点: 一些接线端子包括测试点,可以轻松进行电路测试而无需断开电线。

标签选项: 选择允许您清楚标记终端的块,这在复杂的安装中特别有用。

9.成本考虑

虽然预算不应该是唯一的考虑因素,但找到物有所值的接线端子非常重要。

比较选项: 查看不同的制造商和型号,找到成本和质量之间的平衡。

长期投资: 有时,前期多花一点钱可以减少维护和更换需求,从而节省长期成本。

为什么正确的接线端子很重要

选择正确的接线端子可确保:

可靠的连接: 防止可能导致火花、过热或故障的连接松动。

安全: 正确额定的接线端子有助于防止过载、触电和潜在的火灾。

耐用性: 正确的材料和设计可以延长装置的使用寿命,减少维护或更换的需要。

结论

选择合适的 DIN 导轨安装接线端子 对电气安装的成功和安全至关重要。通过考虑额定电流、材料、尺寸和环境条件等因素,您可以做出明智的决策,从而构建可靠、安全、高效的电气系统。无论您是电气工程师还是 DIY 爱好者,务必确保您的接线端子满足特定应用的必要要求。

想要了解更多信息或需要帮助选择合适的接线端子?请联系 格孔奇 寻求专家指导并了解我们为您的电气需求量身定制的各种产品!